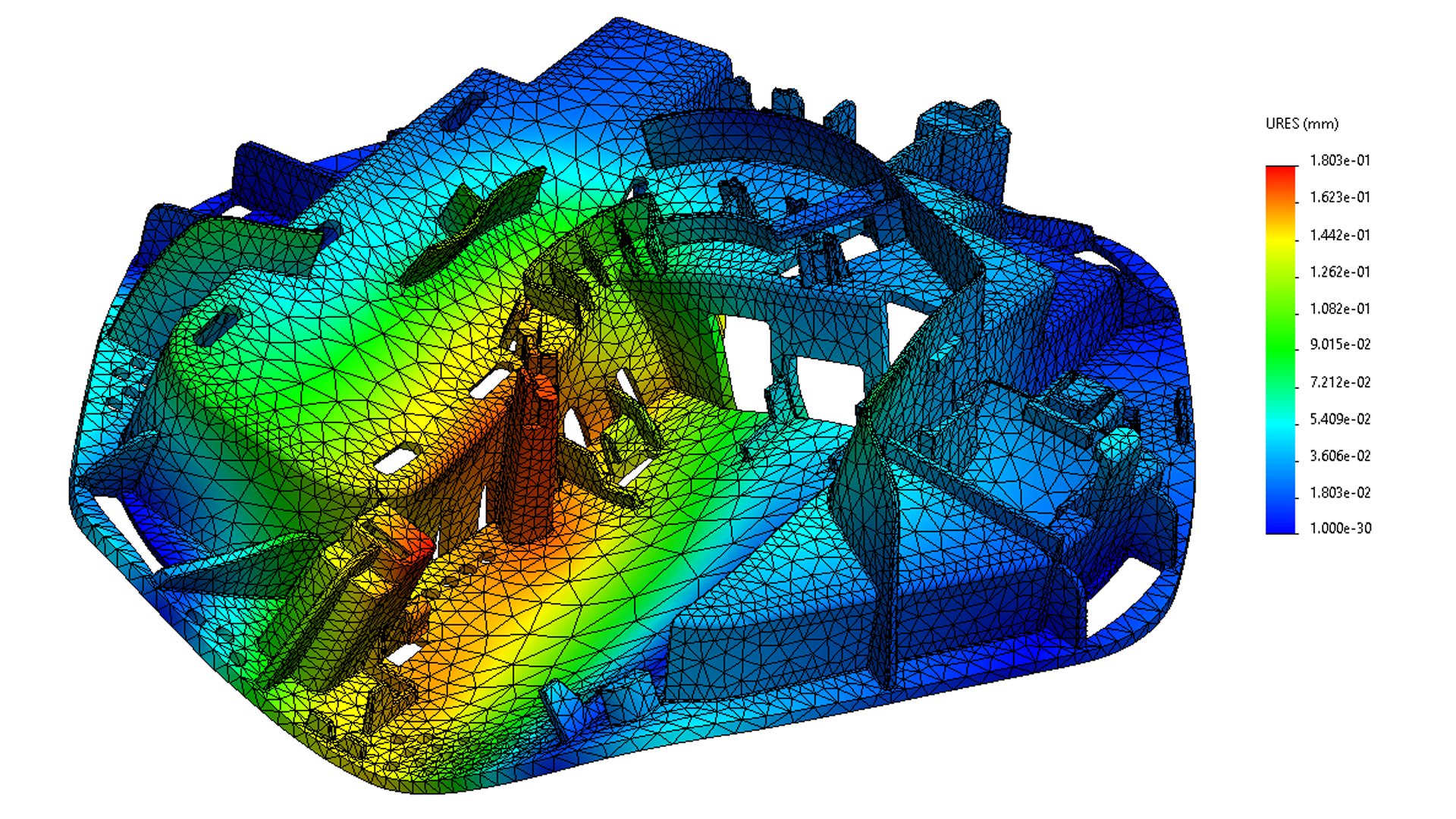

Analysis

Within an automotive context, our innovative designs are validated using a variety of analysis tools, allowing us to identify potential weak links in the system at the design stage and take remedial action ahead of the prototype phase. Our analysis tools include:

Durability Analysis of complete drivetrains, subjected to application specific load collectives

Contact Analysis of individual tooth meshes, including shaft deflection, lead angle modification and transmission error prediction

Finite Element Analysis

Classical Gear Analysis

Spur and Helical Gear Analysis according to ISO 6336

Bevel Gear Analysis according to ISO 10300

Hypoid Gear Analysis according to Klingelnberg

Classical Shaft Analysis

Shaft Strength according to DIN 743

Classical Bearing Analysis

Bearing Life according to ISO 281